Industrial Pipeline Specialties: We can provide total Logistics services, from crating, wrapping, hazardous packing to transportation via Ocean, Air, Truck and Rail. We will follow all marking, packing and document requirement. We can deliver at Ex-works, FOB, FAS, DDU & DDP (per Incoterm latest edition).

Are you a customer and would like an estimation or Budget Price to allocate internal funds for a job ? Are you an Engineer, Construction or Fabrication Shop preparing a Bid presentation ? We can assist you with: Budget Prices, Technical Specifications, Choosing Material, Manuals and Catalogs, Logistics Requirements, etc…

ITF Industrial Pipeline products include;

- Cold drawing

- Hot drawing

- Bimetallic

Materials of Construction include

- Carbon Steel

- Alloy steel

- Stainless steel

- Incoloy®

- Inconel®

- Monel®

- Hastelloy®

- Duplex

- Uranus

- Nickel

- Copper and alloys

- Titanium

- Aluminium

- Other Alloys

Flanges: Flange styles including: Welding-neck, Lap-joint, Blind, Slip-on, Threaded, Socket-weld, Blank, Orifice, Anchor, and Spaces.

Materials of Construction include;

Inconel®, Monel®, Hastelloy®, Duplex, Uranus, Nickel, Copper and alloys, Titanium, Aluminium and Other Alloys.

Cast Iron strainers 250# FF, Carbon Steel to 300, 600 2500#, flanged, butt weld, Socket Weld. Carbon & Stainless Steel basket Strainers to 300#, Duplex Strainers 150# Flanged & NPT, Fabricated T-Strainers. Please contact Office for details.

Cast Iron strainers 250# FF, Carbon Steel to 300, 600 2500#, flanged, butt weld, Socket Weld. Carbon & Stainless Steel basket Strainers to 300#, Duplex Strainers 150# Flanged & NPT, Fabricated T-Strainers. Please contact Office for details.

Chainwheel Operaters in ductile iron and stainless steel. Hammer-blow chain wheels, Floor stands & Valve extensions.

Industrial Pipeline Specialties

Ethylene is a leading manufacturer of high performance, seamless fluoropolymer lined components designed to protect and restore equipment used in chemical, petrochemical and pharmaceutical industries. We offer a broad range of both standard and customized corrosion resistant products lined with seamless PTFE fluoropolymers.

Flexijoint®, Ethylarmor®, FLO-VU® and pHampler® are registered trademarks of Ethylene LLC.

Protection for your downstream equipment

The Ethylene T-Line Strainer™ delivers maximum flow and chemical resistance while protecting your downstream equipment from the catastrophic damage of in-line debris. The strainer housing is lined with ETFE (standard) or PFA (optional) and the basket is solid PTFE. T-Line Strainers™ are rated at 150 psi, available in sizes 2″ to 8″ and can operate continuously up to 400°F. Andronaco T-Line

Dimensions

| Size (in) | A (in) | B (in) | C (in) | D (in) | Drain Size(in) | Weight (lbs) | Diagram | |

|---|---|---|---|---|---|---|---|---|

| 2″ | 13.625 | 19.188 | 11.000 | 11.000 | 2 | 112 |  Enlarge Enlarge | |

| 3″ | 13.625 | 19.188 | 11.000 | 11.000 | 2 | 112 | ||

| 4″ | 13.625 | 19.188 | 11.000 | 11.000 | 2 | 124 | ||

| 6″ | 16.250 | 23.250 | 13.750 | 13.500 | 2 | 280 | ||

| 8″ | 18.250 | 23.250 | 13.750 | 13.500 | 2 | 300 | ||

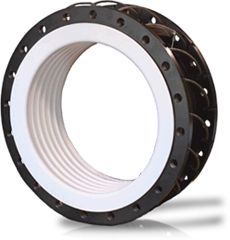

Ethylene Flexijoint PTFE expansion joints are flexible connectors and tremor barriers designed to compensate for misalignment, absorb expansion and contraction, and isolate vibration and shock in process piping, tanks and pumps. They also offer a low spring rate to protect stress sensitive FRP, glass or graphite equipment. Flexijoints are available in sizes 1/2″ to 42″ and from 2 to 12 convolutions for maximum movements.

Ethylene Flexijoint PTFE expansion joints are flexible connectors and tremor barriers designed to compensate for misalignment, absorb expansion and contraction, and isolate vibration and shock in process piping, tanks and pumps. They also offer a low spring rate to protect stress sensitive FRP, glass or graphite equipment. Flexijoints are available in sizes 1/2″ to 42″ and from 2 to 12 convolutions for maximum movements.

Flexijoint has almost universal chemical inertness, high and low temperature resistance, invulnerability to ozone and sunlight, outstanding flex life, and low acoustical impedance (sound dampening properties). Andronaco Flexijoint

Overview: Bellows Flex Joint

Ethylene Corporation’s Flexarmor Flexijoint expansion bellows combine the high pressure rating of a metallic expansion joint with the high temperature, near universal corrosion resistance of PTFE. They are designed for services where the unreinforced Flexijoint PTFE bellows is unsuitable.

Seamless, heavy walled, isostatically molded PTFE liners provide excellent resistance to permeation. This high integrity liner offers a superior alternative to the conventional PTFE spray coated or seamed liner. They are subjected to uncompromising quality control before and after lining of the bellows.

Pressure ratings for Flexarmor bellows are as high as 200 psig. The metallic outer bellows features uniform wall thickness and multiple ply construction for increased flexibility. These bellows are available in most nickel alloys including Monel, Inconel and various types of stainless steels. Available designs include; universal joints, hinged-pinned and slotted, and gimbal types. Versatile manufacturing techniques accommodate customization of Flexarmor bellows flanging, overall length, movements and spring rates.

The FLO-VU 360L sight glass; 1″ through 12″ diameter, features a full 360° unobstructed view with the high temperature and near universal corrosion resistance of PFA.

Double-sure Dual Containment Glass Sight Flow Indicators are specifically designed to provide an extra level of safety, reliability and protection in high pressure and high temperature conditions typically found in ultrapure processing environments.

Dip Pipes and Spargers: Ethylarmor is a PTFE lined and covered armored dip pipe or sparger designed exclusively for the rigorous demands of agitating vessels or the high stress of injection. Also available is Ethylene’s Solid PTFE dip pipes and spargers for non-agitated services.

Reactor Sampling / Monitoring & Control System

The pHampler dip tube is available in standard 2″, 3″ and 4″ sizes – is constructed with schedule 80 carbon steel pipe – completely encapsulated and lined with PTFE to provide maximum chemical resistance and rigidity in hostile agitated vessels.

pHampler® Dimensions

| Dimensions | |||||||||

|---|---|---|---|---|---|---|---|---|---|

| Nominal Size | PTFE Wall | Connecting Flange ‘C’ | Mounting Flange ‘M’ | PTFE Flare | S | Max. OD | Max. L | Dim. H | |

| FC | FM | ||||||||

| 2 | .125 | 1 | 3 | 2 | 5 | 5-1/2 | 2-13/16 | 20′-0″ | 8″ |

| 3 | .125 | 1 | 4 | 2 | 6-3/16 | 5-1/2 | 3-15/16 | 15′-0″ | 8″ |

| 4 | .150 | 1 | 6 | 2 | 8-1/2 | 5-1/2 | 4-15/16 | 15′-0″ | 8-1/2″ |

| 6 | .150 | 2 | 8 | 3-5/8 | 10-5/8 | 7-1/2 | 7-1/16 | 10′-0″ | 12″ |

pHampler TurnKey top-works can be

pHampler TurnKey top-works can bedesigned to meet your monitoring and

sampling requirements.

Stainless steel and

Stainless steel andexotic alloy pHampler systems

also available.

Linned Fittings Overview

Our engineers were given the unrestrained challenge of creating the highest integrity fluoropolymer lined non-standard fittings, column sections and large diameter piping systems. Their only requirement was that our lined equipment outperform the competition in every way. More consistent quality, longer service in the most corrosive enviroments, better looking; simply the highest quality, most flexible lining process worldwide.

We’ve made significant investments in new processes, new equipment and state-of-the-art quality control equipment. This means you have Ethylene’s continuing commitment to meet your toughest and most corrosive requirements.

Large Diameter PTFE Lined Pipe Andronaco Lined fittings

Pipe sections are lined with a heavy-walled isostatically molded PTFE liner with the following minimum PTFE wall thickness.

| Minimum PTFE Wall Thickness | ||

|---|---|---|

| All sizes in inches | ||

| Nominal Size (in.) | Liner Thickness (in.) | Maximum Length (in.) |

| 14 | .250 | 120 |

| 16 | .250 | 120 |

| 18 | .275 | 120 |

| 20 | .350 | 120 |

| 24 | .350 | 120 |

| 30 | .365 | 108 |

| 36 | .375 | 108 |

| 42 | .975 | 60 |

| Typical Properties of DuPont Fluoroplastics | |||

|---|---|---|---|

| PTFE | PFA | ETFE | |

| Melting Point, °F | 621 | 580 | 520 |

| Upper Service Temp., °F | 500 | 500 | 300-350 |

| Tensile Strength, at RT psi | 2,500-4,000 | 4,500 | 6,500 |

| Ultimate Elongation, % at RT | 225-450 | 300 | 100-300 |

| % at 482°F | 350 | 500 | |

| Flexural Modulus, 103 psi at RT | 40-90 | 100 | 200 |

| 103 psi at 482°F | 4 | 10 | |

| Coefficient of Friction | .02-.26 | .23-.29 | .40 |

| Chemical Resistance | Outstanding | Outstanding | Excellent |

| Cryogenic Service | Outstanding | Outstanding | Outstanding |

Serving | |||||||||||||||||||||||||||

|  |

| What can Mercer Rubber do for you? | ||||||||||||||||||||||||